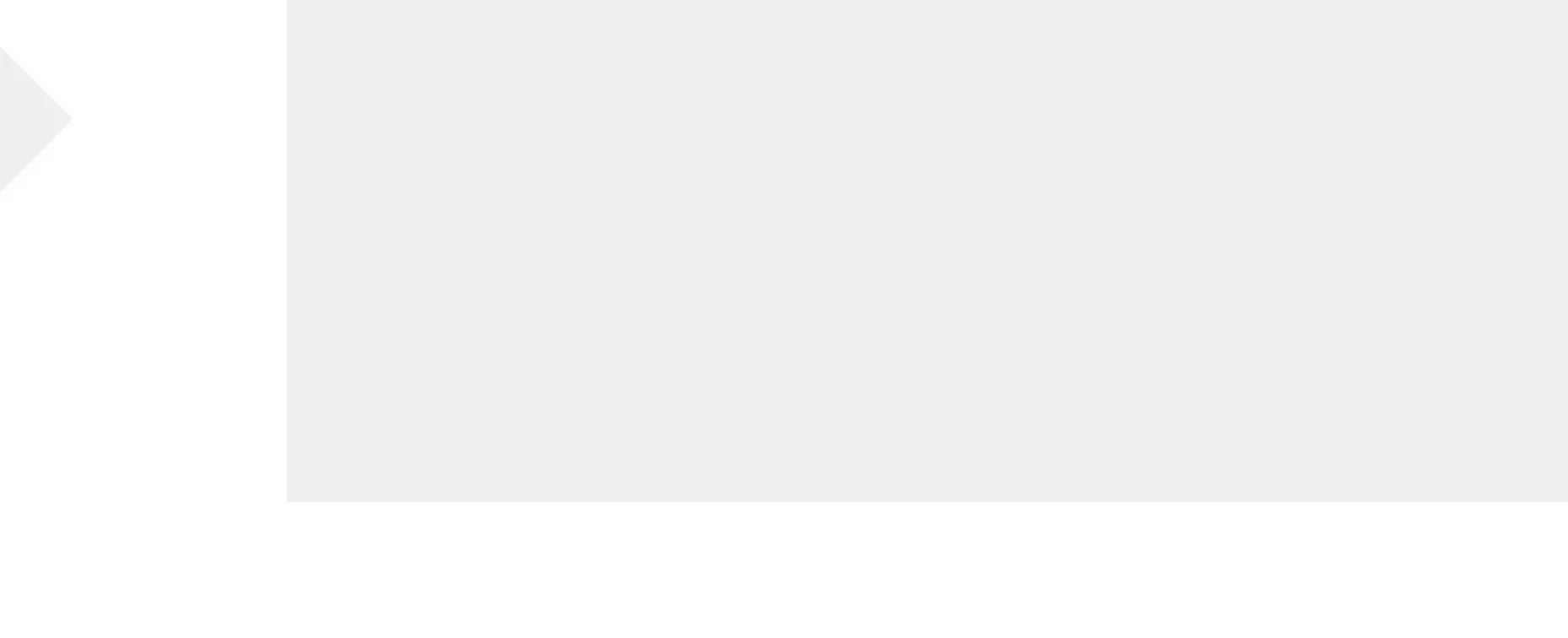

Injection moulding plant

Modern and functional – this is what our Brzeźno Branch, which accommodates a production floor (injection moulding plant), stands for. It is where we produce Tulplast catalogue products and contract projects as part of the services we provide. We work both on customers’ moulds and moulds made in our Tool Room.

Some machines are equipped with manipulators and robots, automatic feed and belt conveyors. Machines are connected to the central cooling system. In addition, the production facility is equipped with dryers for plastic elements. Thanks to the fact that we have the Metal Processing Plant at our disposal, we can make elements for further overmould. In everyday production, we process such materials as: LDPE, HDPE, PA, PP, PS, ABS, PC, PMMA and POM. We can make products from other plastic materials upon the customer’s individual request.

Free quote

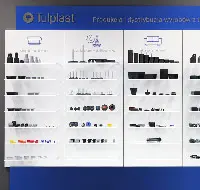

Ultrasonic technology

Ultrasonic technology is used in furniture industry to fix felt on furniture fittings as furniture feet.

Advantages of fixing felt using ultrasonic method:

Accurate and durable fixing of felt without a need of using adhesives and fasteners.

Significantly higher durability of fixing compared with conventionally bonded felt.

When in use, the felt does not change its position and is not subject to any deformations.

Free quote

Advantages of fixing felt using ultrasonic method:

Accurate and durable fixing of felt without a need of using adhesives and fasteners.

Significantly higher durability of fixing compared with conventionally bonded felt.

When in use, the felt does not change its position and is not subject to any deformations.