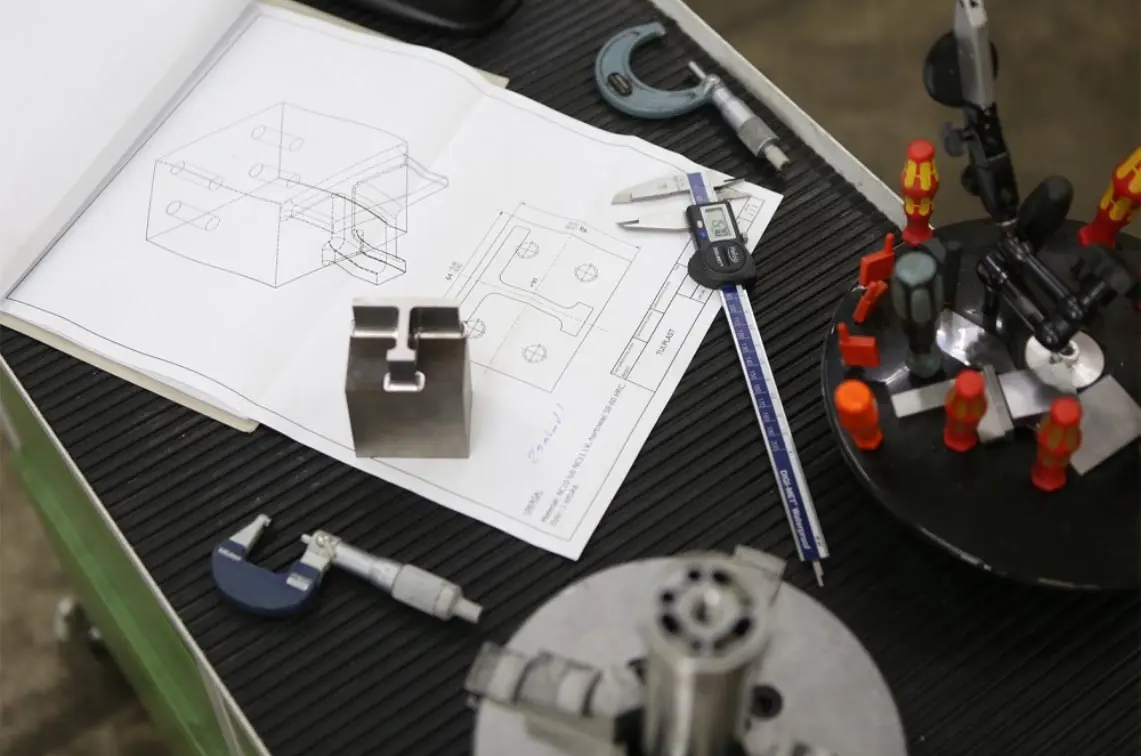

Tool Room

Our own tool room has allowed us to spread the wings. Successive investments in machinery and qualified team of engineers have made it possible for us to take on numerous specialist contract projects. Cooperation between the Tool Room and the Production Department (injection moulding plant) allows an element to be moved to production in no time.

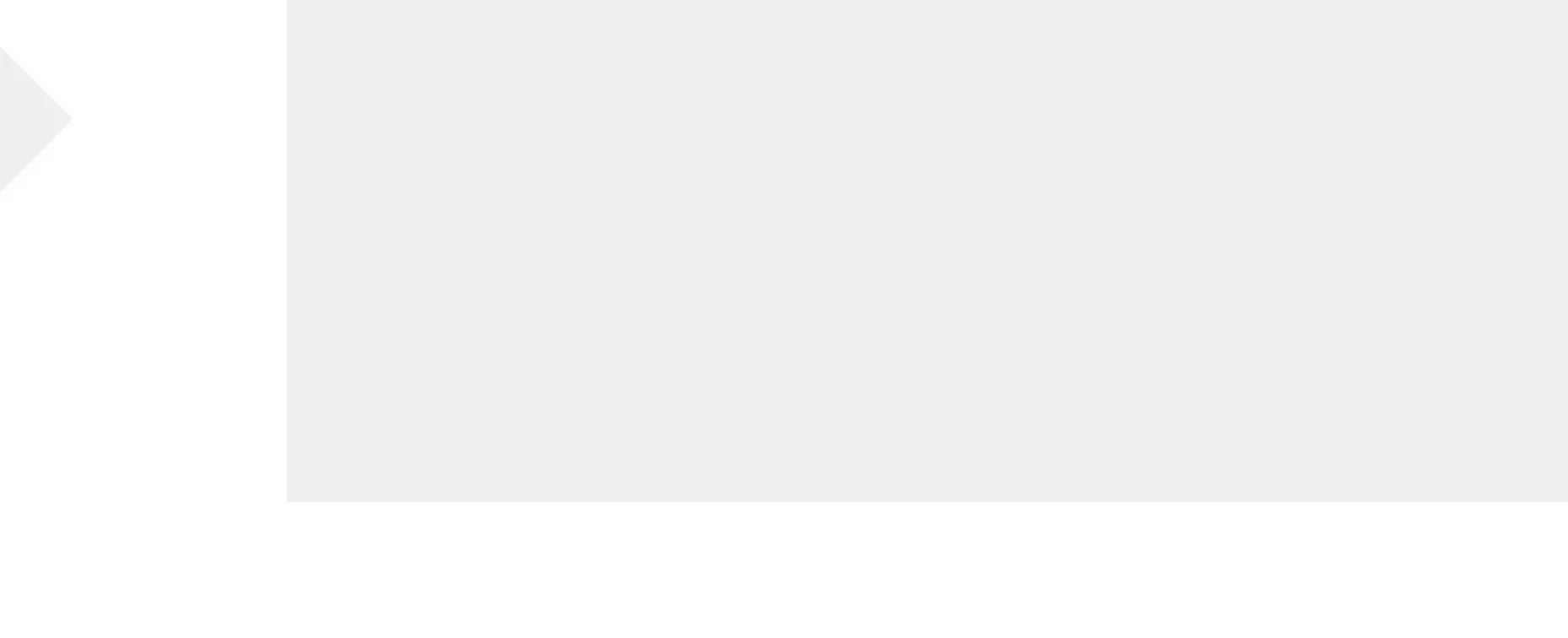

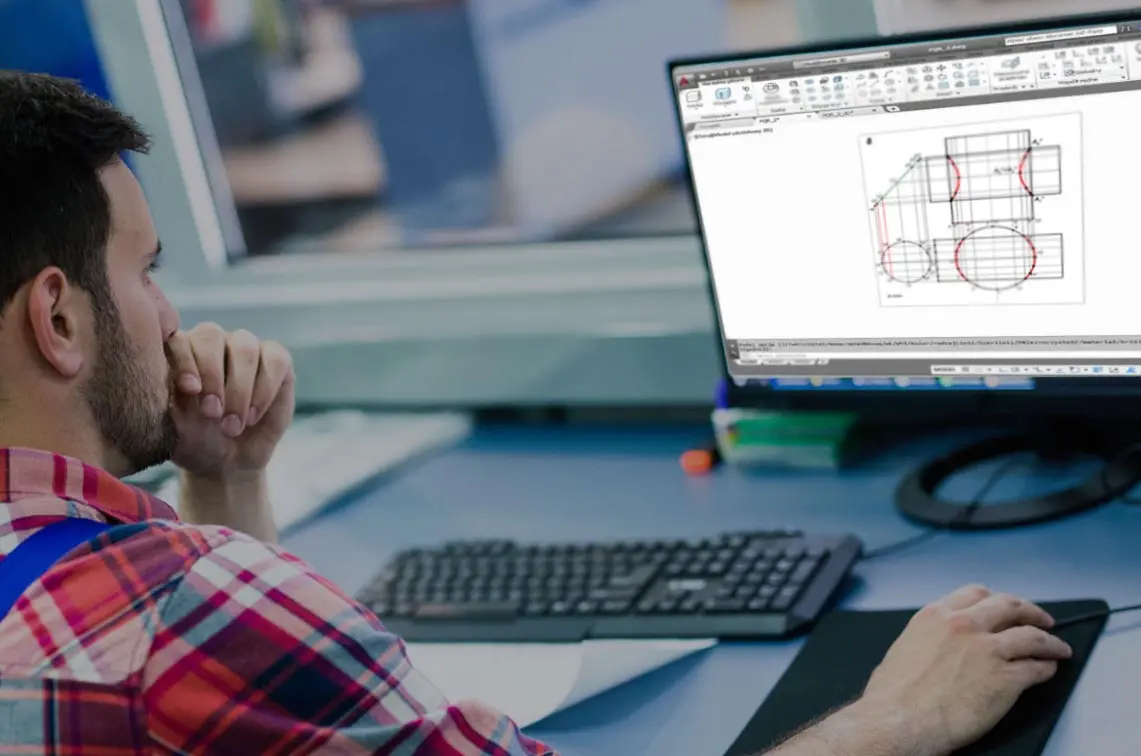

Prototype design and creation

In order to visualise a product, improve a design or minimise potential errors, we create prototypes using a 3D printer.

Free quote

Modern machinery:

OKUMA 4-axis vertical milling machine,

HAAS 3-axis milling machine,

STAR automatic lathe,

MAZAK lathe,

AGIE CHARMILLES FP350 electric discharging machine with an electrode stock,

SODICK AG400L wire electric discharging machine,

ACCUTEX EDM die sinker,

surface grinder,

measuring equipment.

Free quote

HAAS 3-axis milling machine,

STAR automatic lathe,

MAZAK lathe,

AGIE CHARMILLES FP350 electric discharging machine with an electrode stock,

SODICK AG400L wire electric discharging machine,

ACCUTEX EDM die sinker,

surface grinder,

measuring equipment.