Have questions?

+48 61 815 70 16

+48 61 815 70 16

order@tulplast.pl

order@tulplast.pl

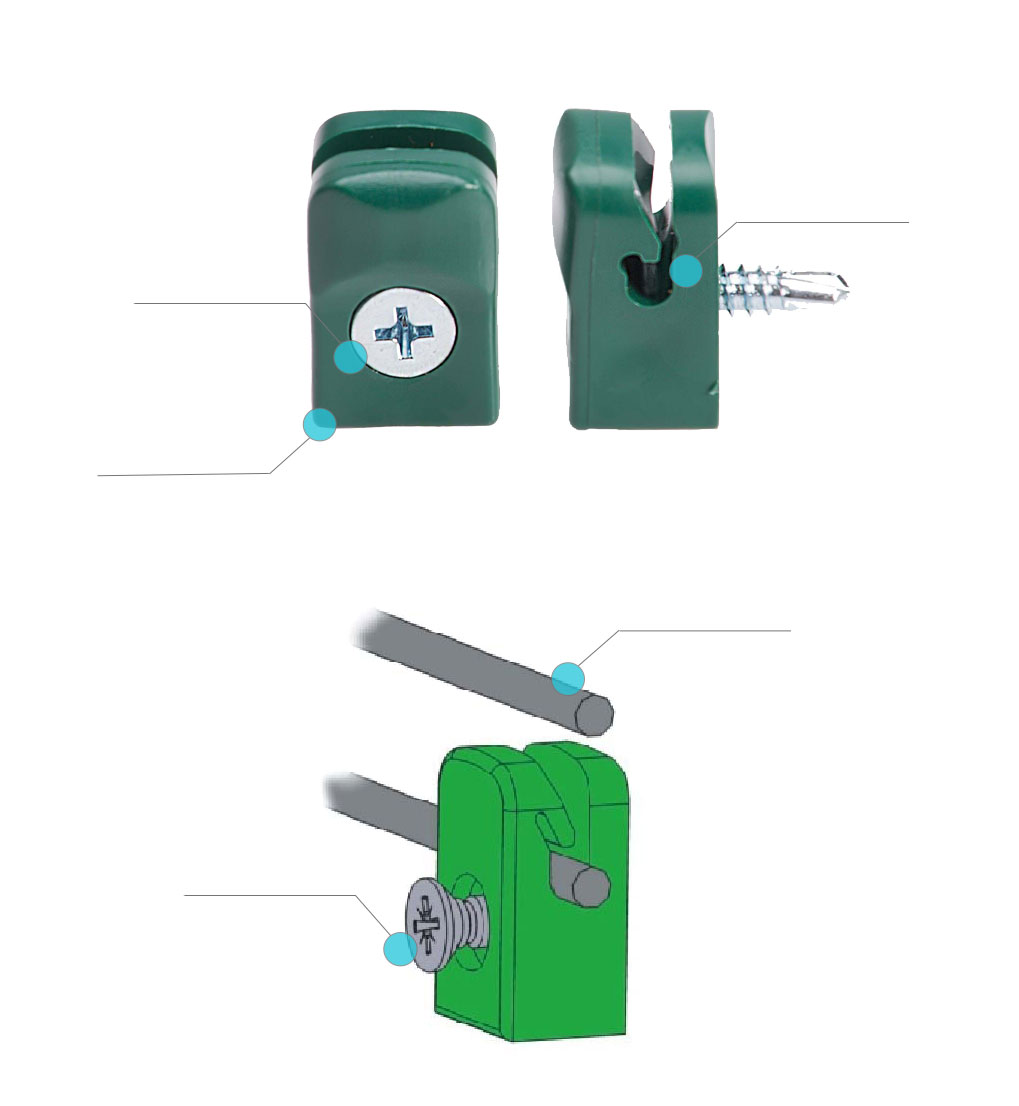

Screw fixed wire holder made of HDPE, standard colors: black, gray, green or brown. Can be made to order in other colors. Used to attach wire when installing fence nets.

Additional properties:

Standard: self-drilling screw 4.8 x 25 with Phillips head.

Option: Self-drilling screw 4.8 x 25 with hexagon head.

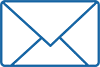

Install the screw fixed wire holder on fence posts with a pipe diameter from 38 mm to 60 mm and a wall thickness from 1.5 mm to 2.2 mm, using a self-drilling screw type PD/A - 4.8x25 mm with a countersunk head or type PD/A/2 - 4.8x25 mm with a hexagonal head.

1. Mark on the fence posts with a center punch the points where the tension wire will run.

Standard installation assumes three levels of wire:

2. Check that all markings are in a straight line. Use a mason’s string line or a laser level for this.

3. Position the screw fixed wire holder at the marked point. Make sure the screw fixed wire holder is straight and its loop faces upward – the tension wire must always be inserted from above the screw fixed wire holder.

4. Screw the eyelet into the post using a self-drilling screw and a screwdriver. The self-drilling screw will drill through the steel and anchor itself in the post.

5. Leave a gap of approx. 4 mm between the screw fixed wire holder and the screw head. Then insert the tension wire through the eyelet loop.

6. Switch the screwdriver to torque mode (approx. 4 Nm) to avoid over-tightening.

7. Do not press the screw fixed wire holder too hard with the screwdriver – excessive tightening may damage the screw fixed wire holder by over-compressing it with the screw.

8. Repeat all steps for each intermediate fence post.

We are a manufacturer with over 40 years of experience in the production of plastic and metal products. We have a large warehouse to maintain a deep inventory. Our committed customer service team will quickly handle even the biggest and most demanding orders, including custom-made orders. To ensure top-quality service to our customers, we will gladly examine your requests and prepare an attractive quote. Requests should be sent to: order@tulplast.pl

Complementary products: